- Home

- Business Optimization

- Solutions

- Construction Safety

- Dust control

DUST DECREASES PRODUCTIVITY AND INCREASES MAINTENANCE COSTS

Our solutions to support health and safety in the construction industry

More HSE experts are focusing on dust in the construction industry

Because of its potentially hazardous consequences on health and safety, dust can lead to severe health issues as well as loss of productivity and work comfort.

Dust and Construction

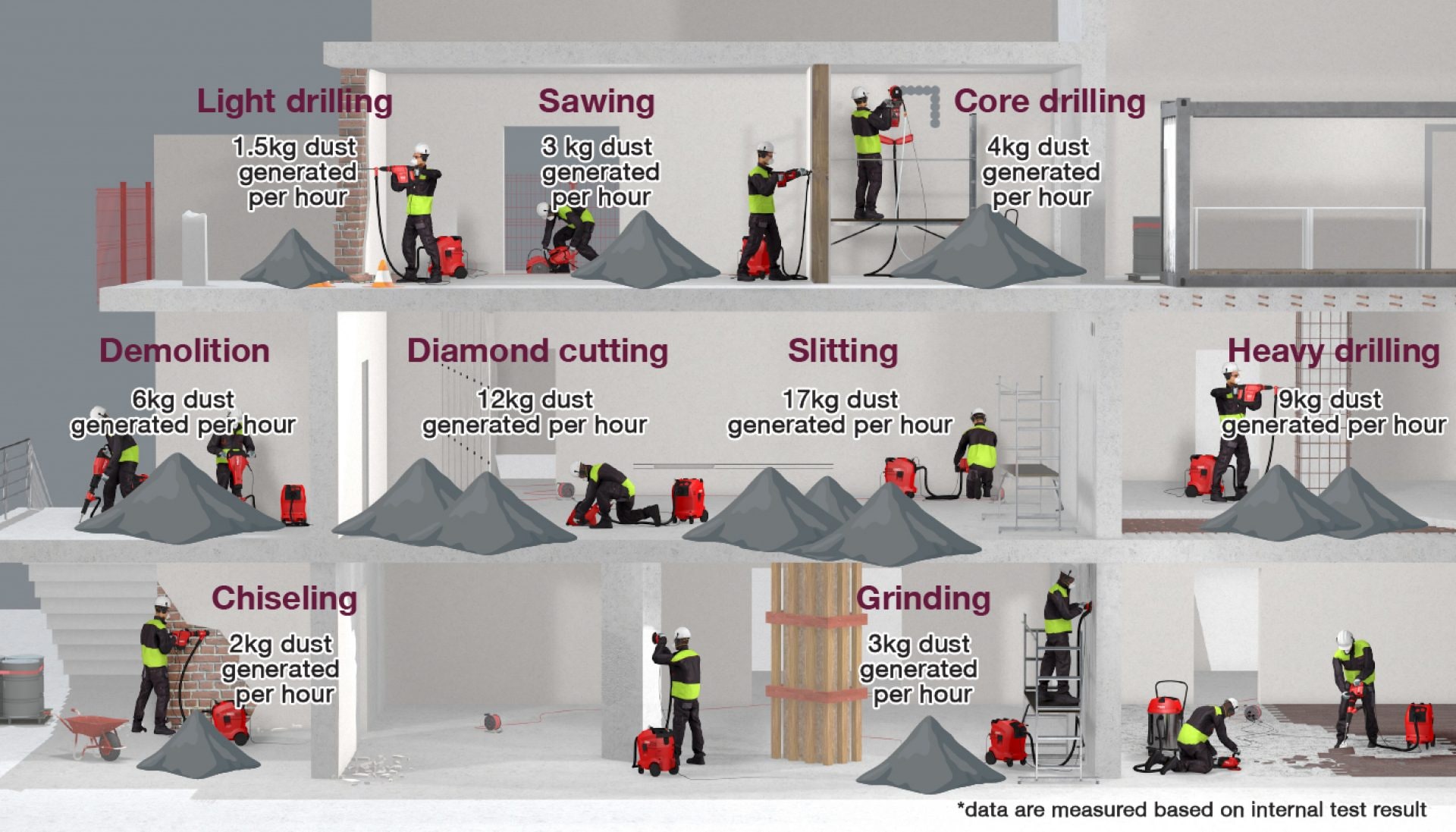

Dust is generated by abrasive treatment of materials like drilling, chiseling, sawing or grinding. But dust can also occur through circulation when it is blown up by wind or by movement of dusty material through transportation or while mixing powdery material, e.g. when preparing cement.

Depending on the material processed different types of dust occur. One of the most relevant to the construction industry is:

Dust with crystalline structure: generated by abrasive treatment of material that contains silica e.g. sandstone, concrete, mortar or tile. It contains respirable crystalline silica (RCS)

Now add up all the work done on your construction site on a normal work day – that can be a lot of dust your employees must deal with, right?

Dust can pose a threat to Health and Safety

A shockingly high number of people die each year of lung cancer because of over-exposure to respirable silica dust. Others suffer from dust-related diseases so badly that they can no longer work. So, dust can have severe consequences to your workforce if not tackled head-on. Several national and international organizations have realized the urgency of the issues and launched initiatives and campaigns to combat dust at the workplace.

What are the consequences?

When the human body inhales dust, natural defense mechanisms kick in e.g. sneezing, coughing. But those human defense mechanisms are limited and for some kinds of dust ineffective. Special care must be taken when working with materials containing silica.

Silica is a natural material. About 27% of our earth crust is covered with it. It occurs in many materials common on constructions sites like sandstone, concrete, mortar, tile, brick and more.

When processing these materials, fine dust that contains respirable crystalline silica (RCS) occurs. Over-exposure to these RSC particles can be very dangerous because they reach deep into our lungs and settle in our lungs’ air sacks (alveoli). Over time scar tissue is produced and reduces the ability to breath-in oxygen. This incurable disease is called silicosis.

Dust not only affects the lungs – it can also lead to other issues like eye and skin irritation or allergic reactions. Most of these diseases will take a longer time to develop but with high exposure to dangerous dust it can also develop quite fast and can raise drastic problems like:

- Reducing ability to work

- Reducing quality of life

- Permanently damaging health

DUST DECREASES PRODUCTIVITY AND INCREASES MAINTENANCE COSTS

Most people would prefer to work in a clean environment where body, clothes and surroundings stay clean and no personal protective equipment must be worn.

Working in clouds of dust also increase the risk of injuries due to reduced visibility and can distract employees because of eye irritations, sneezing, coughing or nose blowing. But that’s not the only reason to take control of dust. You can significantly increase productivity and lower maintenance costs with appropriate measures against dust by:

• Reducing preparation time: no or minimal time sealing off the area required before work starts

• Reducing cleaning: depending on the application you can save up to 99% of cleaning time

• Reducing damage of fixtures and fittings: like carpets, furniture and other furnishings

• Increasing lifetime of tools: by up to 60% and of inserts by up to 20%

• Increasing application speed: up to 20% with cleaner and sharper tools

How do you measure dust on the jobsite?

We know why it makes sense to minimize dust exposure on jobsites. But what exposure limits should you be aiming to avoid?

In the UK, there are official guidelines on exposure limits which you need to be aware of. Firstly, the HSE’s Control of Substances Hazardous to Health (COSHH) regulations define Workplace Exposure Limits (WELs) for specific dusts. The WEL for respirable crystalline silica (RCS) dust is 0.1 mg per cubic meter averaged out over an 8-hour workday. Other respirable dusts are limited to 4 mg per cubic meter and other inhalable dusts to 10 mg per cubic meter, averaged out over the same time period [2]. The latter is roughly equivalent to only the weight of a 2 Euro Cent coin.

Similar standards are imposed across Europe, meaning that wherever you have jobsites within the EU you have the challenge of keeping your team’s dust exposure to low levels.

So how can you reduce construction dust inhalation? We recommend following the "STOP Principle", Which is Substitution, Technological, Organizational, and Personal Protection.

Substitution: eliminate the risks of dust by using alternatives

Wet diamond drilling

Keep jobsites cleaner by collecting slurry created during wet diamond drilling. Units such as the DD-WMS water management system supply, filter and collect slurry for easy disposal.

DD-WMS 100 water management system

Direct fastening

Make the switch to the BX 3 battery-powered nailer, designed to be a cleaner, quieter and virtually dust-free alternative to drilling.

BX 3 battery-powered nailerTechnical: products to reduce dust inhalation

Hilti has decades of experience in preventing, managing and removing construction dust. At our Dust Research Center in Kaufering, Germany our Dust Experts are part of a community actively developing relevant standards like EN 50632.

Hilti power tools, accessories and inserts (such as drill bits, discs, blades or chisels), are designed as harmonized Dust Removal Systems (DRS) to maximize the amount of harmful dust removed at source and collect it efficiently with high-performance vacuum cleaners.

Consequently, 95% of our power tools can contribute to virtually dust-free, and therefore, healthier jobsites.

Applications include:

Drilling

Remove up to 97% of dust with integrated dust removal systems like the TE-DRS, compatible with the TE 6-A22 cordless rotary hammer.

Similarly, the TE-YD hollow drill bit – when used with SDS combihammers such as the TE 50-AVR and VC 40-UL wet and dry vacuum cleaners – provides virtually dust-free concrete drilling.

TE-DRS dust removal system TE-YD hollow drill bit

Chiseling

Remove up to 95% of dust when chiseling with tools like the TE 2000-AVR concrete demolition hammer, combined with the TE DRS-B dust management and a universal vacuum cleaner like the VC 40-UL.

TE DRS-B dust removal system

Cutting

Virtually dust-free concrete cutting, when you combine Angle Grinders tools with cutting dusthood to a VC 40 vacuum cleaner

Angle Grinders Dust Removal system for Cutting and Slitting

Grinding

Virtually dust-free results: when you combine tools such as the DGH 130 concrete grinder with a VC 40-UL vacuum cleaner.

DGH 130 Concrete grinder Dust Removal system for Grinding

Vacuum cleaning

Hilti vacuum cleaners are powerful, highly efficient, and designed to withstand the harshest jobsite conditions.

In addition, automatic filter cleaning technology briefly reverses the flow of air inside the system every 15 seconds, to prevent dust build-up on the filter, and keep suction high.

VC Vacuum cleanersOrganizational: measures to reduce dust exposure

The third stage of the "STOP principle" is to find and put in place organizational measures that help minimize dust exposure.

One practical method is job rotation, switching teams between dusty tasks, and thereby reduce exposure times for each individual. Similarly, many in the construction industry have introduced the ‘Ban the Broom’ initiative, meaning construction dust is vacuumed rather than brushed into the air.

Personal protective equipment: where health risks remain

Lastly, if there is no way for tradespeople to remain below dust limit values, then it’s important to use relevant personal protective equipment (PPE). Dust masks, eye protection, disposable overalls and gloves are all essential kit, even when using virtually dust-free tools. In conditions where dust levels are unavoidably high, respirators may be necessary for maximum protection against dust inhalation.