- Home

- Heavy Duty Tools

- Technology

DUST, HEAT, TIGHT DEADLINES?

Tool technology for tough jobsite conditions

We know you can’t afford breakdowns. Therefore, we test all our tools under the same tough conditions as the jobsites you work on daily. Dust and overheating are the main concerns in the lifetime of a power tool. Dust interferes with the mechanical functioning of the tool and excessive heat causes premature wear of the tool components. Our tools can withstand the harshest jobsite conditions and are designed to last at least twice as long as their stated lifetime.

HOW WE TACKLE DUST

Our tools are equipped with unique multiple-chamber lubrication, high-performance seals, brushless motors and robust chucks.

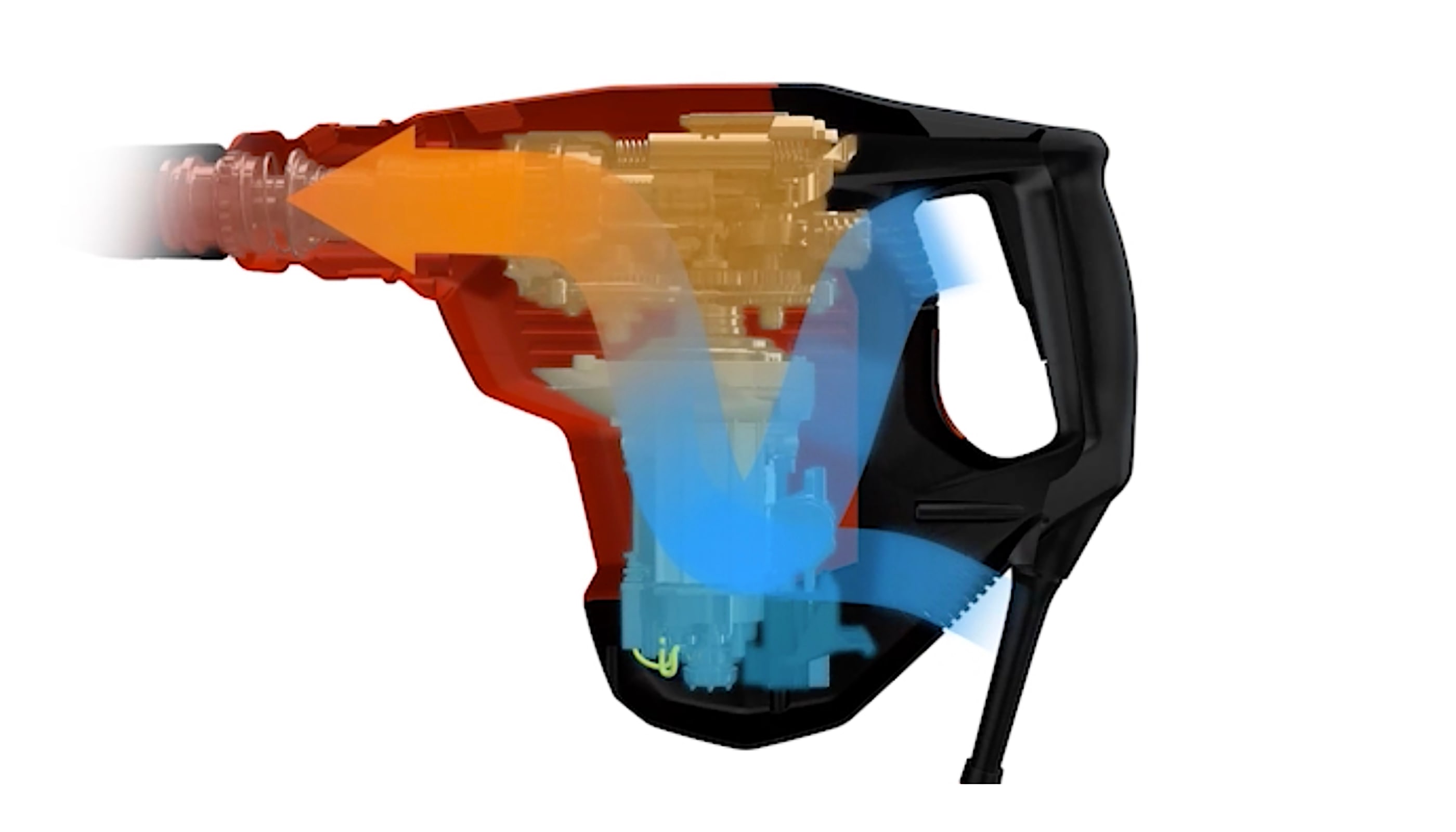

HOW WE TACKLE HEAT

Optimized airflow and oil lubrication around fast-moving parts cool the tool from the inside and out.

HOW WE TEST FOR LONG RUNTIME

We test our tools as if they are on real jobsites, drilling millions of holes by hand as well as with test rigs. Some of our tools have motors with up to 300 hours carbon brush lifetime.

NO ADDITIONAL REPAIR COST

We believe so strongly in the sturdiness of our tools that we will cover any repair costs for up to 2 years from the date of purchase.